Resins and Filler Compounds

Gateway Composites two-component, high strength, high modulus epoxy resin systems used as the primer and saturant for Gateway Composites carbon fiber systems and kits (Fiberlock™ and private label brands). Resin is combined with carbon, glass and basalt fabrics for wet-layup composites providing strengthening and reinforcement to structural members.

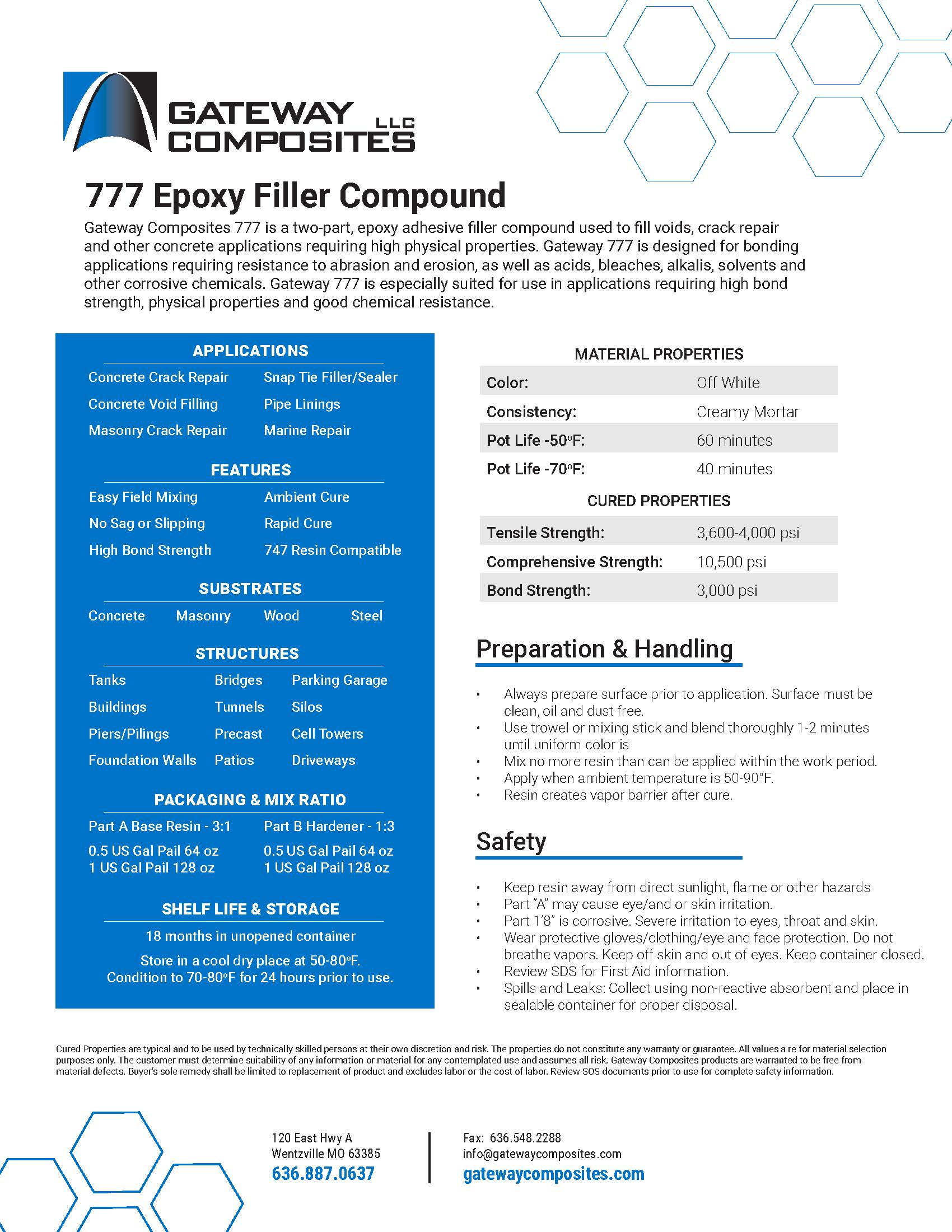

777 Epoxy Filler

Compound

Gateway Composites 777 is a two-part, epoxy adhesive filler compound used to fill voids, crack repair and other concrete applications requiring high physical properties. Gateway 777 is designed for bonding applications requiring resistance to abrasion and erosion, as well as acids, bleaches, alkalis, solvents and other corrosive chemicals. Gateway 777 is especially suited for use in applications requiring high bond strength, physical properties and good chemical resistance.

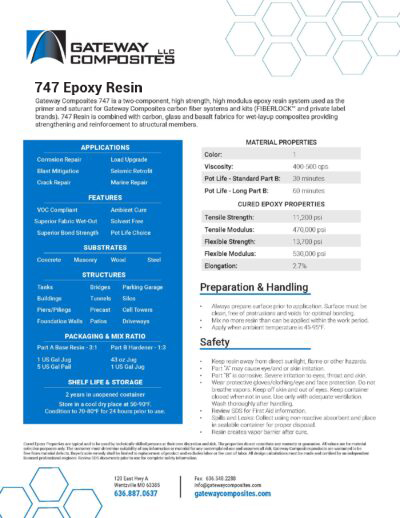

747 Epoxy Resin System

Gateway Composites 747 is a two-component, high strength, high modulus epoxy resin system used as the primer and saturant for Gateway Composites carbon fiber systems and kits (Fiberlock™ and private label brands). 747 Resin is combined with carbon, glass and basalt fabrics for we-layup composites providing strengthening and reinforcement to structural members.

MATERIAL PROPERTIES

|

Color: |

Off White |

|

Consistency: |

Creamy Mortar |

|

Pot Life -50oF: |

60 minutes |

|

Pot Life -70oF: |

40 minutes |

CURED PROPERTIES

|

Tensile Strength: |

3,600-4,000 psi |

|

Comprehensive Strength: |

10,500 psi |

|

Bond Strength: |

3,000 psi |

PREPARATION & MIXING

- Always prepare surface prior to application. Surface must be clean, oil and dust free.

- Use trowel or mixing stick and blend thoroughly 1-2 minutes until uniform color is

- Mix no more resin than can be applied within the work period.

- Apply when ambient temperature is 50-90°F.

- Resin creates vapor barrier after cure.

SAFETY

- Keep resin away from direct sunlight, flame or other hazards

- Part “A” may cause eye/and or skin irritation.

- Part 1’8” is corrosive. Severe irritation to eyes, throat and skin.

- Wear protective gloves/clothing/eye and face protection. Do not breathe vapors. Keep off skin and out of eyes. Keep container closed.

- Review SDS for First Aid information.

- Spills and Leaks: Collect using non-reactive absorbent and place in sealable container for proper disposal.

MATERIAL PROPERTIES

|

Color: |

1 |

|

Viscosity: |

400-500 cps |

|

Pot Life – Standard Part B: |

30 minutes |

|

Pot Life – Long Part B: |

60 minutes |

CURED PROPERTIES

|

Tensile Strength: |

11,200 psi |

|

Tensile Modulus: |

470,000 psi |

|

Flexible Strength: |

13,700 psi |

|

Flexible Modulus: |

530,000 psi |

|

Elongation: |

2.7% |

PREPARATION & HANDLING

-

Always prepare surface prior to application. Surface must be clean, free of protrusions and voids for optimal bonding.

- Mix no more resin than can be applied within the work period.

- Apply when ambient temperature is 45-95°F.

SAFETY

Keep resin away from direct sunlight, flame or other hazards.

- Part “A” may cause eye/and or skin irritation.

- Part “B” is corrosive. Severe irritation to eyes, throat and skin.

- Wear protective gloves/clothing/eye and face protection. Do not breathe vapors. Keep off skin and out of eyes. Keep container closed when not in use. Use only with adequate ventilation. Wash thoroughly after handling.

- Review SDS for First Aid information.

- Spills and Leaks: Collect using non-reactive absorbent and place in sealable container for proper disposal.

- Resin creates vapor barrier after cure.

Cured Epoxy Properties are typical and to be used by technically skilled persons at their own discretion and risk. The properties do not constitute any warranty or guarantee. All values are for material selection purposes only. The customer must determine suitability of any information or material for any contemplated use and assumes all risk. Gateway Composites products are warranted to be free from material defects. Buyer’s sole remedy shall be limited to replacement of product and excludes labor or the cost of labor. All design calculations must be made and certified by an independent licensed professional engineer. Review SDS documents prior to use for complete safety information.